INTRODUCTION:

Information Technology and its growth have set a massive revolution in warehouses and textile industry. With the help of processing techniques, these industries are serving maximum benefits.

On the other hand, success in any industry/organization is a combination of strong processing techniques or we can say that better processing of their raw data. To manage quality in Textile plants with new trends and technology is a new concept. Every industry is dependent on some sort of digital systems to operate their data.

Nowadays, Every single organization has one goal- Increase productivity for better profitability. However, this doesn’t only depend on sales we acquire but also on the quality in less time we provide. Introducing various Data processing tool and Techniques can surely help these industries to produce extensive production with quality.

Therefore, in the textile industry today, Image processing plays a vital role. Before proceeding ahead with more details – Let’s quickly shed some light on-

Jump to Section

What is Image processing?

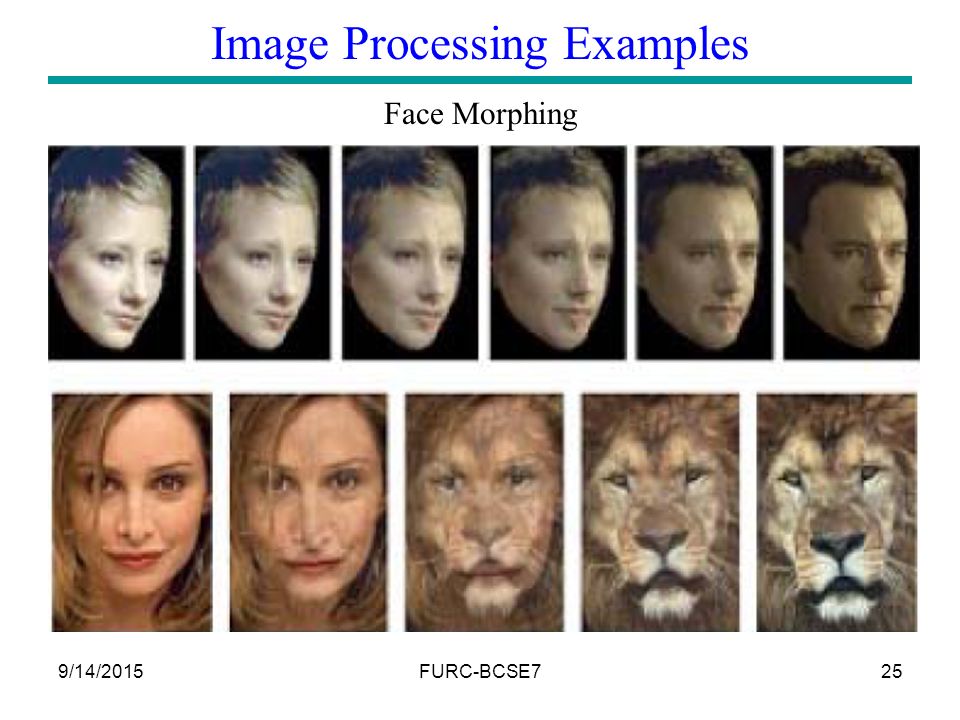

Image processing is a method by which we can convert an image into a digital form and perform some operations on it in order to get an enhanced image or extract some sort of useful information from it.

Now, usually, an Image processing system includes treating images as two-dimensional signals while applying already set processing methods to them. It’s a type of signal dispensation in which you take the input like an image or video and the output may be some characteristics associated with that image. It is one of the most rapidly growing technologies nowadays. It also forms a research area with Engineering and computer science areas too.

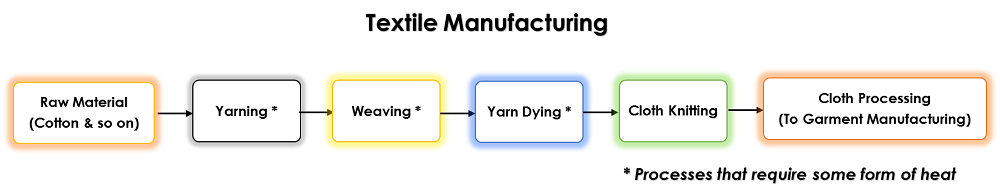

Textile Industry and its processes

There are two types of Textile Industry i.e Organized and Unorganized. The organized industry is also referred to as centralized sector or Mill sector which has spinning mills, composite mills. On the other hand, Unorganized is called as Decentralized which has Handlooms, Power looms, Hosiery and khaddi units also processing units.

But both of them have similar production process as follows-

1- Gathering Raw material.

2- Yarning.

3- Weaving.

4- Yarn dying.

5- Cloth knitting.

6- Cloth processing.

IMAGE PROCESSING IN TEXTILE INDUSTRY

Generally, Image processing is the process of analyzing data from different perspectives and summarizing it into useful information or output. It helps users to analyze data from different verticals like ratio, angles, and categories.

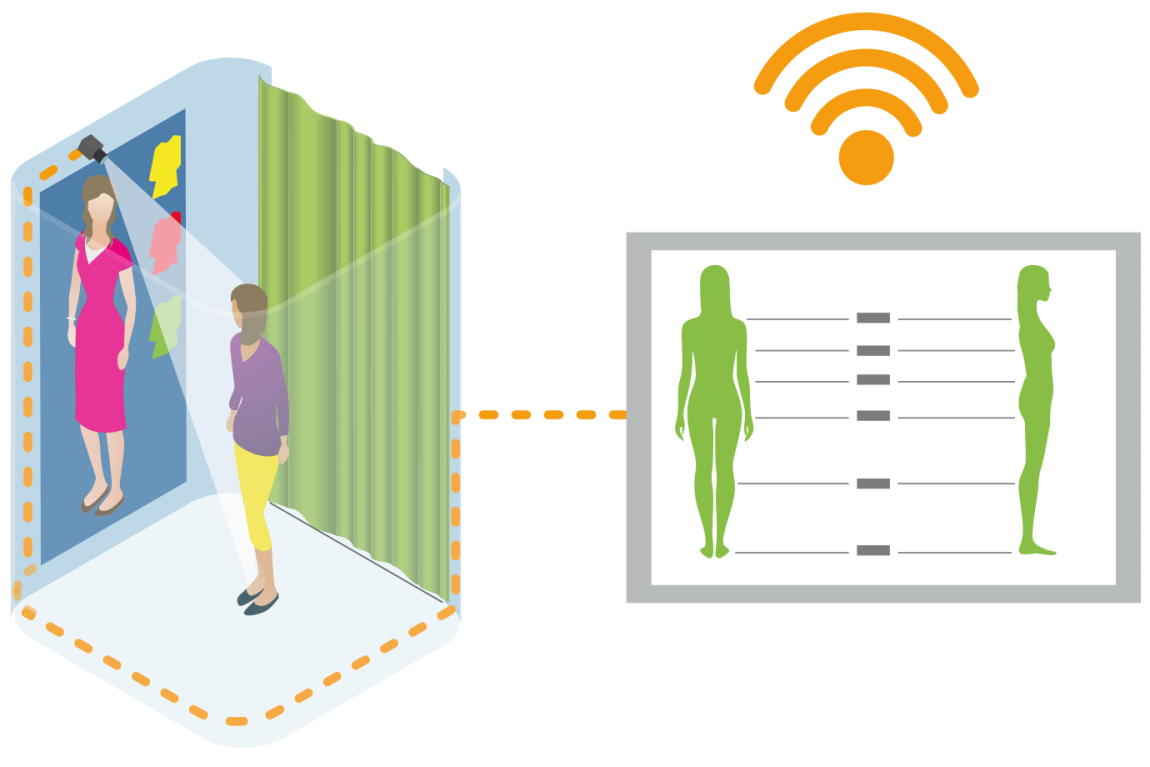

Image processing and its techniques offer the most encouraging road to the future improvement of a fast and dependable instrumental strategy for production, powerful controls of the various material process and material item qualities. Picture processing is particularly helpful in material assembling and reviews, including surface assessment and processing of textile surface attributes. Digital processed pictures offer promising application and exceptionally quick, precise, and target processing of an extensive variety of material properties.

Have a look at this:

Digital Image handling can be utilized for testing Cotton development, Cross area production, Trash content, appearance, Fiber crease, Fiber fineness, Fiber width, Fiber surface property. For yarn, it can test cross segment, equality, appearance, bristliness, turn, mix examination, turning strain. For Fabric Wrinkle, Drape, Pilling, Abrasion, Structural investigation, the Non-woven structure, Knitted structure.

As of late, some processing strategies have been acquainted which measure the yarn width, contort edge and furriness in a non-destructive manner. A spatial system is produced to separate the contort point through the processing center picture. At that point, a Fourier change procedure is connected to yarn pictures to quantify the introduction of the fiber on the yarn surface. At last, the final product is obtained with various filters applied to it.

Yarn diameter

Yarn breadth is an important determinant of numerous texture parameters and properties e.g. cover factor, porosity, thickness, air porousness, texture appearance and so forth. There are several strategies kinds of sensors utilized for showing the yarn unevenness. These instruments vary in the standard of estimating and the ratio of assessment of yarn diameter. These strategies are more solid and to build up a connection between the outcomes all process are acquired through various methods.

It is extremely important to work in order to investigate a texture weave structure with a prodding needle and stripped human eye. Accordingly, it has turned out to be important to create a counterfeit vision and robotization to explore texture weave structure, in this manner evading the same time giving exhaustion, better dependability, and enhanced precision. By utilizing image processing preparing techniques, a framework to identify both weave examples and yarn shading plans are created.

How Textile quality control is getting better with Image Processing

Quality is the top most priority of any vendor/user which is the only demand in the industry. Vendors are ready to shed money if they get the best quality. Therefore, Image Processing helps these textile vendors to produce their product with high-quality standards.

The dynamic advancement of computers now makes expansive potential outcomes for their application, including distinguishing and estimating the geometrical measurements of even the small requirements including material items. Image processing allows a more definite examination of such fundamental basic parameters of direct material items as thickness, shagginess, and the number of turns. This system likewise empowers the estimation of other components of the outer structure of material items, for example, wind parameter and material thickness.

On the other hand, we can say that Image processing system empowers pictures of longitudinal and transversal cross areas of strands to be acquired, the measurements to be additionally surveyed, and pictures of direct material items make which permit the perception of yarn deficiencies and the assurance of their causes.

The pictures acquired can make two-dimensional and three-dimensional material items, including pictures of joined yarn-end associations and assessments of their accuracy.

With the help of image processing, industries are serving the best output as follows-

1- Vendors stick with the initial requirement.

2- Vendors get the exact product/output as required.

3- Quality delivery.

4- Less expense.

5- Better productivity.

And many more. As we know that Image processing converts an image into a digital form and perform some operations which send the signal to the operating mechanism for the product manufacturing. The final product after processing is mapped with the initial requirements before the output.

There are many more major benefits which Image processing is serving to the Textile industry. Please take a look.

Image processing benefits in Textile Industry

Quality is the first need of any customer and the most important part, especially in the textile world. Modern textile industry focus on providing the best output with less budget keeping customer point of view in mind along with the latest trends in the market.

Lets us check out How Image processing is beneficial in better quality control with these below pointers-

1- Helps in Planning, processing and final execution as per the initial requirement.

2- Reduce operational cost and losses.

3- Helps in assessment and evaluation of Orders/Products which are in process and finished.

2- Helps to rectify defected products which can lead to poor performances in the market.

3- Optimize better quality standards for all conditions within the timeline.

4- Always helps in improved production and process controls.

5- Saves excessive usage of raw data and helps to gather precise information.

6- Helps in less wastage and labor.

7- Helps in reduction of operational cost and scientific tolerance.

8- Helps in better employment with latest techniques.

9- Helps in maintaining Vendor commitments with better quality and production.

10- Finally, Customer satisfaction and Trust.

Therefore, the above points not only pushed the Textile industry to grow with higher efficiency but also many major sections are also driven by Image processing.

Let’s review more

The cutting-edge Textile industry has been confronting various difficulties in making an excellent assembling condition. Such a situation requires enhanced quality, expanded generation and adaptability, available stock and minimization of cost.

For this reason, the Textile world and its processing basically require on the web, constant, and dynamic controls. Image processing is one such system that converts the pictures into numerical shapes. It is a field that is quickly transforming the pictures into meaningful pieces of information in digital formats. Utilizing advanced processing techniques allows more definite solutions of essential parameters for textile items as thickness, furriness and number of turns, additionally used to discover the texture deserts, fiber introduction in nonwovens, and so forth.

This processing strategy is for estimating the fiber introduction in nonwovens. Fiber introduction assumes a critical part in characterizing appearance, execution, and processability of the nonwovens. It mostly relies upon the consistency of the networks. The nonwovens have a uniform mass delivery for better execution and feel. Thus evaluations of fiber introduction are not solid and Image processing methods are accessible to more success.

Conclusion

Image processing in the Textile world has several advantages as compared to other technologies. It serves many processing methods to the initial image in order to get the best and accurate quality image. One more fact of image processing is images are shown in 2 dimensions even more but digital images are shown in multidimensional structures.

One of the greatest advantages of image processing in textile control is- the capacity of the administrator to post-process the picture. Post-preparing of the picture enables the administrator to control the pixel shades to revise picture thickness and complexity, and in addition, perform other handling techniques that could result in enhanced conclusion and less rehashed versions.

I hope with this blog you can have complete idea how Textile quality control is getting better with Image processing. However, do write for any suggestion or query in the comment section.

Thank You for reading!!!

- Business Intelligence Vs Data Analytics: What’s the Difference? - December 10, 2020

- Effective Ways Data Analytics Helps Improve Business Growth - July 28, 2020

- How the Automotive Industry is Benefitting From Web Scraping - July 23, 2020