These days, Big Data Analytics, the Internet of Things (IoT), Artificial Intelligence, Industrial IoT, and many more, have been the current discussions on digital transformations. The term ‘Digital Twin’ enveloping the above principles emerged under digitalization talk.

Information/ Data has played an important/central role for a long time. But today, both industry’s digital and physical worlds are forging a close connection between them because of the growing influence of the Internet of Things (IoT). Because of continuous streams of real-time data, now it is possible to create a digital version of any product or process, which enables manufacturers to predict results more accurately, detect issues sooner, and build better products.

Jump to Section

Firstly, We Need to Understand: What is a Digital Twin?

Let’s go ahead…

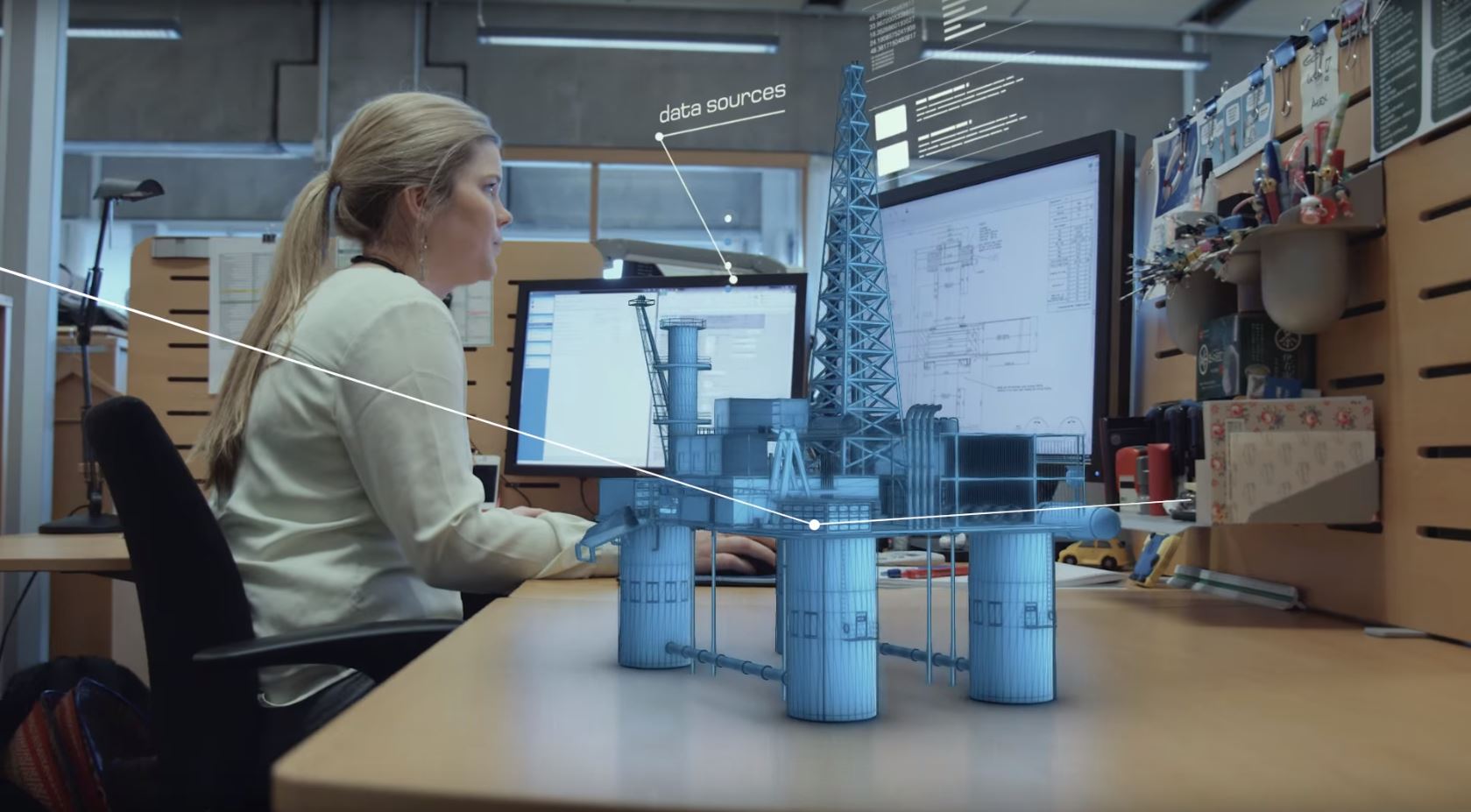

‘Digital Twin’ used to describe a computerized and/or digital version/model of an asset. The asset may be a physical (like sensor or machine) or logical (business process or service) asset. These digital models or digital replicas use data about a physical asset to better understand so that it improves their performance. They used to display information about the physical object collected with systems and sensors.

Everything in the world has some history. So, Digital Twin also has a history.

Let’s talk about this history.

History of the Digital Twin

Let’s start with the origins of the Digital Twin.

Origins of the Digital Twin

Digital Twin, as a concept, was introduced in 2002 at the University of Michigan. Micheal Grieves was the one who introduced it on Product Lifecycle Management (PLM). At that time when this concept was introduced, digital representations of actual physical products were relatively new and immature. But, the truth remained that the information about the asset can be collected. After all, it enables engineers to better understand the working and behavior of the complex systems in order to mitigate “unpredictable, undesirable emergent behavior.”

Early Uses of the Digital Twin

After the Introduction of Digital Twin, it was majorly used by NASA. This was in 2011. The main objective of NASA was to solve the problem of developing and maintaining systems which they would not be able to monitor physically.

Principal Technologist of NASA, John Vickers explains:

“The ultimate vision for the digital twin is to create, test, and build our equipment in a virtual environment. Only when we get it to where it performs to our requirements do we physically manufacture it. We then want that physical build to tie back to its digital twin through sensors so that the digital twin contains all the information that we could have by inspecting the physical build.”

Digital Twin is a trending technology, but the question arises:

Where is the use of this technology and what is the importance of it?

Why Us Digital Twin Technology Important?

The Internet of things (IoT) acts as a foundation for the digital twin technology. Therefore, in the coming days, most IoT platforms will embrace digital twin technology.

Between the extensive consortium of Machine Learning, Artificial Intelligence, and Data Analytics, digital twin predicts issues before they occur in the asset. It is like knowing the future and having the capability to change it accordingly.

This technology takes minimum time to resolve any issues that might occur in the product. It decreases overhead expenditures and downtime as well. It is an integrated way to optimize and monitor the performance of the asset virtually.

Digital Twin Model

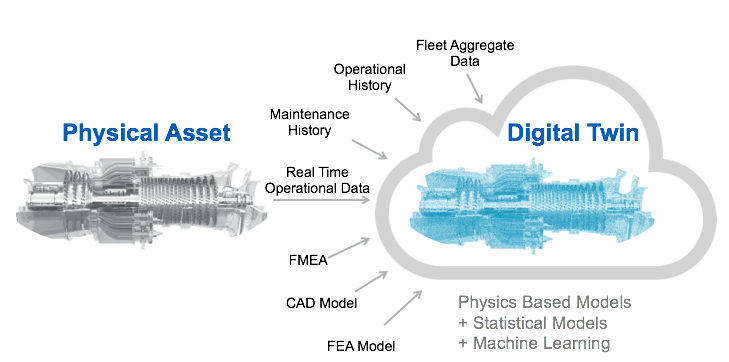

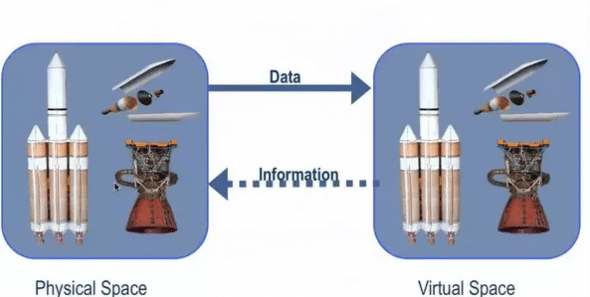

As Dr. Grieves defines, the Digital Twin model consists of three main parts which are as follows:

- Physical products in real space

- Virtual products in virtual space

- Connected data that tie physical and virtual products together

The whole concept behind digital twin is to assemble a large amount of digital information for virtual products; digital information that is almost identical to the physical counterparts. When one gathers digital information, it serves as a twin of the physical information. This information is then embedded/immersed within the physical product by itself and linked to it throughout the lifecycle of the system.

Benefits of Digital Twins

- Makes it possible to manufacture/ produce high-quality products.

- Helps to attain optimization of sustainability and operability.

- Helps in the evaluation of a product’s current and future potential during its lifecycle.

- Extends the life of equipment and assets as it accompanies the physical product during its entire lifecycle.

- Helps in achieving efficient production control.

- Helps in the early discovery of system performance defects by imitating results way before physical processes and product are developed.

- Reduces the operating cost.

- Helps in the continuous improvement of designs and models through captured data.

- Helps to easily cross-reference design details.

Applications of Digital Twin

By applying Digital twin, major changes can be seen within different sectors. It helps organizations to obtain better perception so that they can produce a better product in terms of:

- On product performance,

- Improve customer service,

- Make better operational and strategic decisions, etc.

Some of the Digital Twin Applications are as follows:

- Manufacturing,

- Automobile,

- Retail,

- Healthcare,

- Smart Cities,

- Industrial IoT.

Digital Twin and Manufacturing

In the past, when there was a need to get detailed information about the report of any operating product then it was done personally monitoring that product. But nowadays, Digital Twin is impacting the manufacturing sector. It virtualizes the task by creating and maintaining a digital representation. This also makes the manufacturing of products more efficient and optimized while cutting down prototyping and construction costs. It enables us to predict failures more easily.

In this way, Digital twin is helping to open new methods for improving the productivity of products.

Digital Twin and Automobile Industry

The digital twin concept can be used in the Automobile industry to analyze overall vehicle performance and features through capturing the behavior and operational data of the vehicle. It provides customized service to the customers. Hence the application of these technologies in present-day automobile industry will give the generation what they want.

Digital Twin in Retail

So, do you know what is the main key in the retail sector? If not, here is the answer!

In the field of the Retail sector, the main key is Customer Experience.

Digital twin implementation can play a vital role in expanding the retail customer experience by creating virtual twins for customers. It also helps in better security implementation, instore planning, and energy management in an optimized manner.

Digital Twin and Healthcare

Along with the IoT data, Digital twin has an important part in the field of Healthcare from expenses and savings to patient monitoring, precautionary/preventive maintenance, and providing personalized health care.

Digital Twin and Smart Cities

Now, you may be thinking about how Digital twin helps in the field of Smart Cities.

Here’s the answer!

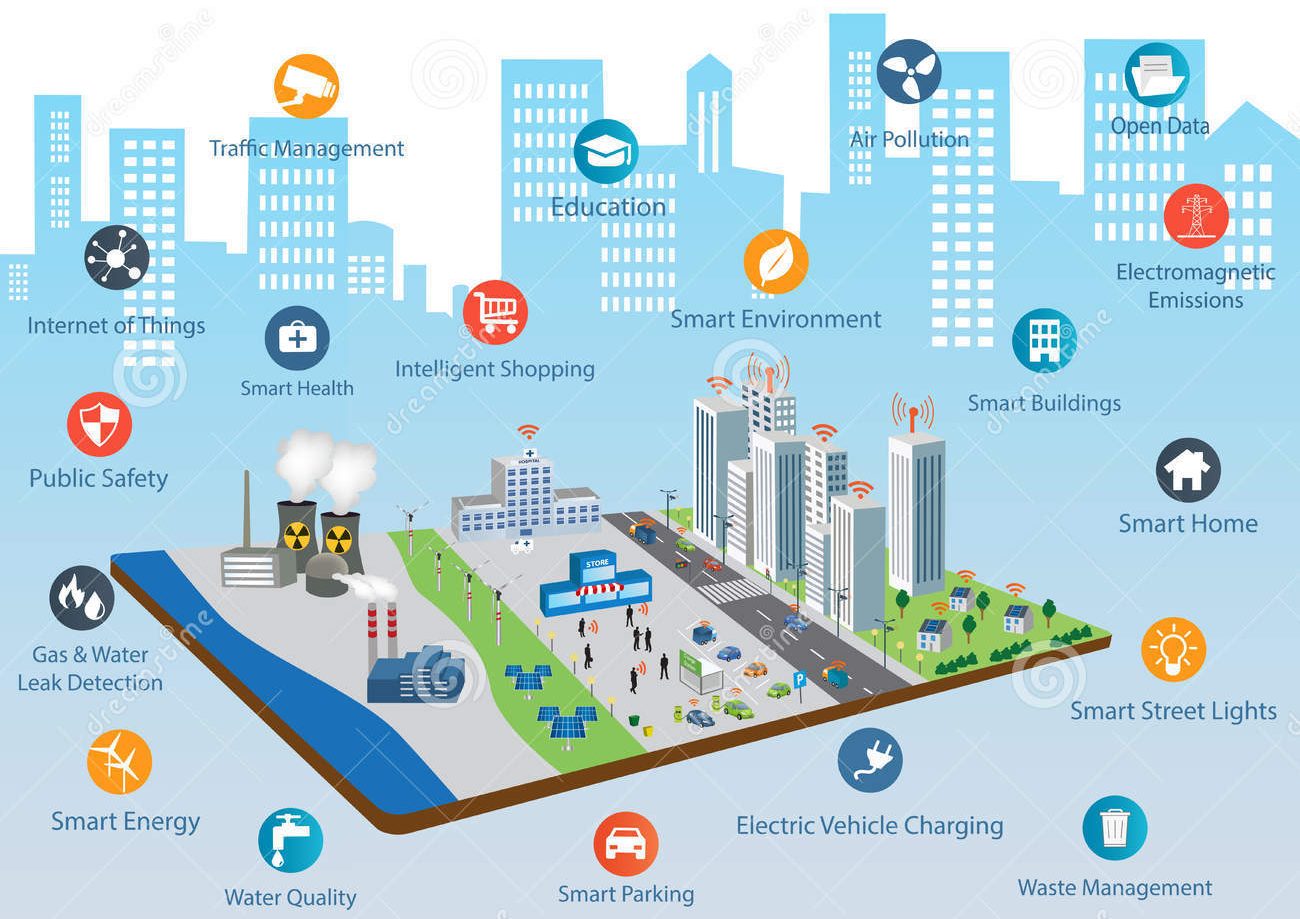

Digital twin along with the IoT data helps in planning and implementation of smart cities with different aspects:

- To enhance economic development.

- Reduction of ecological footprint.

- Efficient management of resources.

- Increase the overall quality of a citizen’s life.

This model can help city planners and policymakers in smart city planning by gaining the perception from various sensor networks and intelligent systems. The data collected from the digital twin model helps them in achieving future decisions.

Digital Twin and Industrial IoT

Industrial firms can digitally monitor, track and control industrial systems. Besides operational data, the digital twin model stores environmental data like location, financial models, configuration, etc. It helps in forecasting the operations and anomalies.

Wrapping Up

Along with IoT, Digital Twin is now demanding technology because it has different advantages in different sectors like manufacturing, healthcare, IT Industries, etc. This technology helps in detecting faults at the earlier stage of the development process. It can predict the future outcomes of the product by virtualization of that product.

So, this is a brief introductory lesson about the Digital Twin and how it is coming on-trend with IoT.

- Business Intelligence Vs Data Analytics: What’s the Difference? - December 10, 2020

- Effective Ways Data Analytics Helps Improve Business Growth - July 28, 2020

- How the Automotive Industry is Benefitting From Web Scraping - July 23, 2020